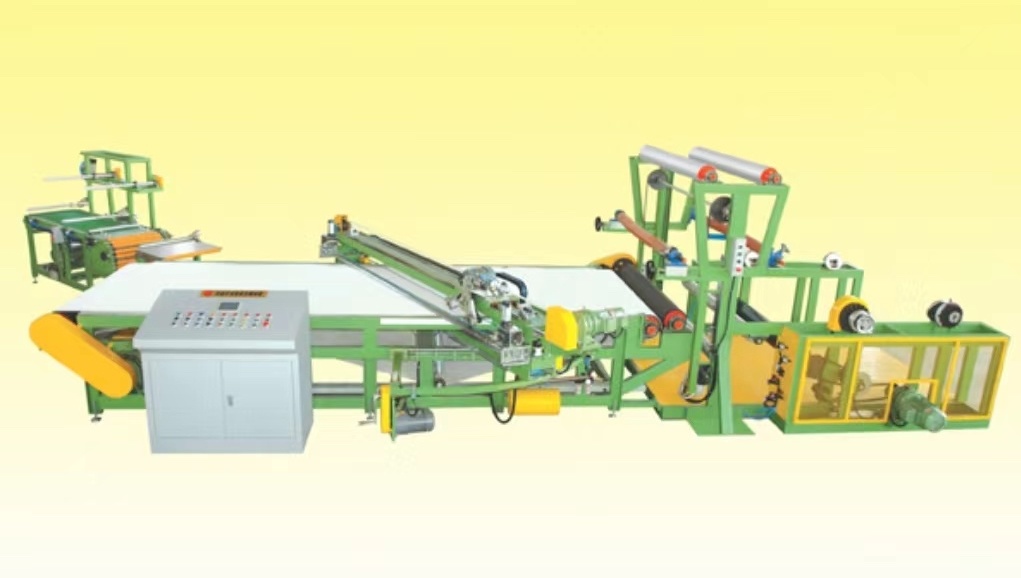

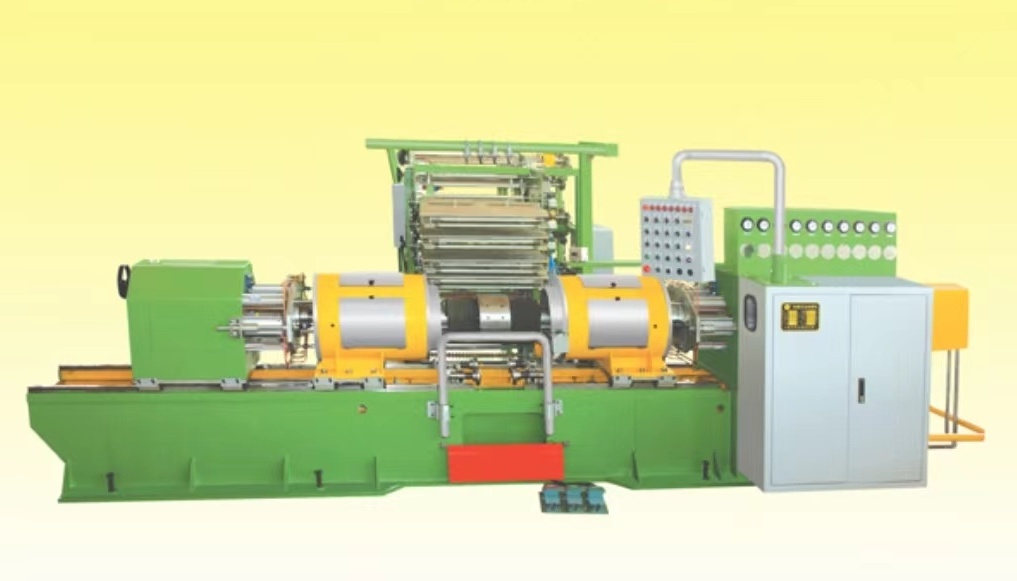

Vertical Batch-off Unit

Slab Cooling Machine The Best Batch-off Unit products play a key role in the production of rubber products. Providing efficient and controllable cooling and peeling processes helps optimize the production process and improve product quality and production efficiency

Keyword:

Laboratory Equipment

Categories:

Batch-off Unit

Tel:

The Best Cooling Batch off Unit products have various advantages in the rubber industry, especially in the cooling and stripping process of vulcanized rubber belts. Here are some of the advantages of this device:

1. Efficient cooling: It can achieve rapid and even cooling of the vulcanized rubber belt, ensuring that the product reaches room temperature quickly. This helps improve production efficiency, reduce the cooling time of the vulcanization belt, and increase production capacity.

2. Prevents adhesion: It prevents adhesion between vulcanized rubber strips through an effective cooling and peeling process. This helps ensure the independence of the vulcanized zone and avoids unnecessary problems in subsequent processing.

3. Maintains product quality: Controlling the cooling process, helps maintain the physical properties and quality of the rubber belt. Ensure that the product can maintain its designed characteristics after vulcanization and improve the quality of the final product.

4. Improve production efficiency: The efficient cooling and stripping process of the Vertical Slab Cooling Unit can help manufacturers complete the production of vulcanized rubber belts more quickly and smoothly. This is especially important for large-scale, high-volume production lines, helping to improve overall production efficiency.

5. The Best Batch-off Unit products play a key role in the production of rubber products. Providing efficient and controllable cooling and peeling processes helps optimize the production process and improve product quality and production efficiency.

Specifications of Vertical Slab Cooling Unit (Batch-off Unit):

|

Item

Model |

Slab thickness |

Slab width |

Belt Speed |

Cutting Speed |

Clamping Motor Power Upgrade |

Total power |

Mesh Belt and Transmission Power |

Fan Power |

Rubber Cutting Length |

Overall dimensions

L×W×H |

Weight |

|

mm |

mm |

m/min |

times/min |

KW |

KW |

KW |

KW |

m |

mm |

Kg |

|

|

XPLL-500 |

3~12 |

20~500 |

11~22 |

10~20 |

1.5 Frequency conversion |

15.14 |

5.9×5 Frequency conversion |

3.74×14 |

0.8~1.2 |

15560x2030x2990 |

~5700 |

|

XPLL-600 |

3~12 |

20~600 |

11~22 |

10~20 |

1.5 Frequency conversion |

15.14 |

5.9×5 Frequency conversion |

3.74×14

|

0.8~1.2 |

15560x2130x2990 |

~6500 |

Previous:

Previous:

Related products

Get product quotes for free

Our staff will contact you within 24 hours (working days). If you need other services, you are welcome to call the service hotline:0411-86666555

ADD

Room 3718,No.9-1.Haifu Road,Dalian Free Trade Zone,China(Liaoning)Free Trade Pilot Area

PRODUCTS