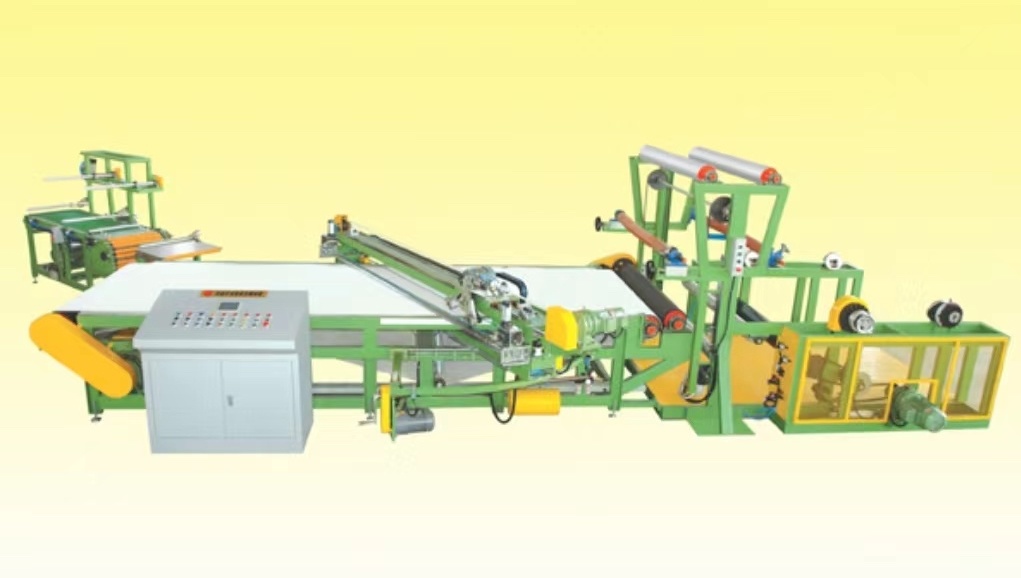

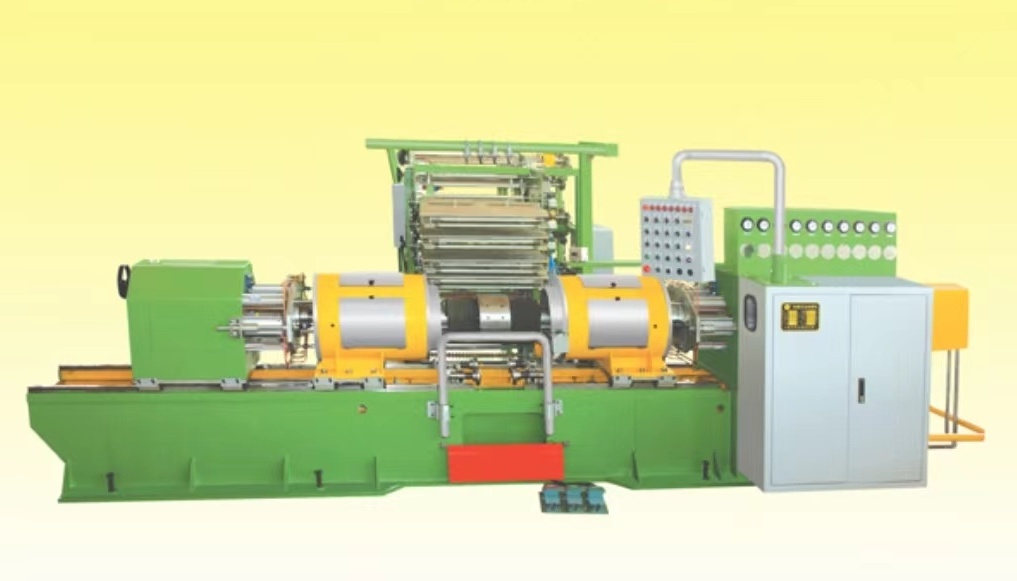

110L internal mixer

Choose the Best Internal Mixer products to achieve higher mixing efficiency, more consistent product quality, and better process control in rubber and plastic processing, thereby increasing production efficiency and reducing production costs

Keyword:

Laboratory Equipment

Categories:

Products

Rubber Internal Mixer

Tel:

There are multiple reasons for choosing the Best Internal Mixer products in the rubber and plastics industry. These reasons involve production efficiency, product quality, cost control, process control, and other aspects.

Efficient mixing and dispersing: Through its unique mixing structure and design, the mixing and dispersing process can be completed in a relatively short time. The movement of the agitator and the shape of the mixing chamber fully stress the raw materials, achieving efficient mixing and dispersion, ensuring that additives, pigments, reinforcing agents, etc. are evenly distributed in the rubber or plastic.

Consistency and Quality Control: It helps improve product consistency and quality stability. By accurately controlling the parameters during the mixing process, such as temperature, pressure, mixing time, etc., precise control of product quality can be achieved to ensure that each batch of products meets specifications.

Suitable for a variety of materials: It is not only suitable for rubber, but also widely used in the mixing and processing of polymer materials such as plastics. This versatility makes this equipment widely applicable in different production scenarios, providing convenience for the production of diverse products.

Improved production efficiency: Its efficient mixing and dispersing process brings significant improvements in production efficiency. It can complete the mixing process more quickly, reduce production cycles, and improve overall production efficiency.

Cost control: Its efficient mixing process can bring lower production costs. The fast and uniform mixing process reduces energy consumption and the need for manual intervention, lowering production costs.

Choose the Best Internal Mixer products to achieve higher mixing efficiency, more consistent product quality, and better process control in rubber and plastic processing, thereby increasing production efficiency and reducing production costs.

Next:

Previous:

Next:

Related products

Get product quotes for free

Our staff will contact you within 24 hours (working days). If you need other services, you are welcome to call the service hotline:0411-86666555

ADD

Room 3718,No.9-1.Haifu Road,Dalian Free Trade Zone,China(Liaoning)Free Trade Pilot Area

PRODUCTS