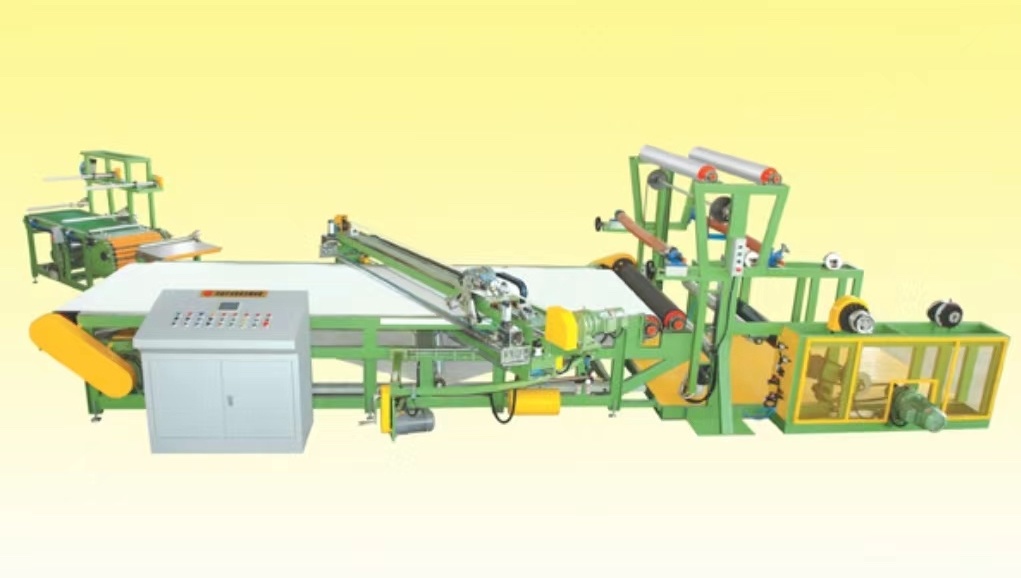

Extruding Sheeter

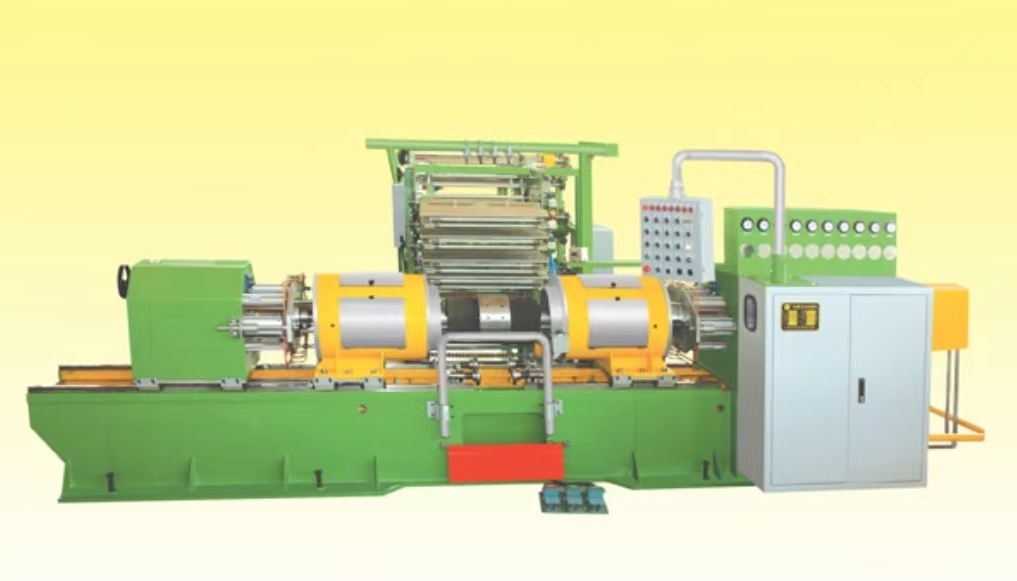

Double Conical-Screw Extruding Sheeter is designed to forcibly extrude and sheet compounded rubber, plastic, synthetic resin or nonmetallic material in continuous production, it has high efficiency and is ideal for working with internal mixers or dispersion mixers.

Keyword:

Laboratory Equipment

Categories:

Extruding Sheeter

Tel:

Overview of Sheet Extruder Machine

The quality pp sheet extruder machine For sale is a key piece of equipment specially used to produce polypropylene sheets. PP is a thermoplastic with good heat resistance, chemical corrosion resistance, and excellent mechanical properties, so PP sheets are widely used in various fields. The main function of the sheet extruder is to melt PP resin particles in a high-temperature environment and then extrude them into sheets with the required thickness for subsequent processing and product manufacturing.

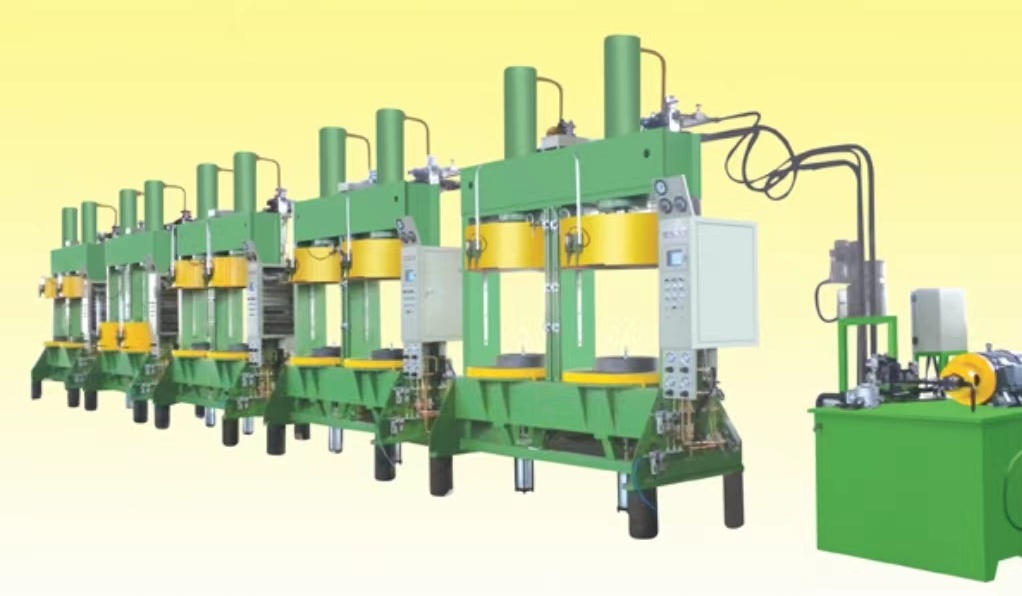

Sheet extruders usually consist of a feeding system, a melting system, an extrusion system, and a cooling system. In the feeding system, PP resin particles are transported to the melting system of the extruder, and through high-temperature heating and mixing, the PP resin is melted into a uniform melt. Next, the molten PP material passes through the extrusion system and is extruded into sheets with the required thickness through the extrusion head. Finally, the extruded PP sheet is rapidly cooled through a cooling system to solidify and maintain the required physical properties.

The extruder sheet machine plays a vital role in the field of plastic processing. As the demand for environmentally friendly and lightweight materials continues to increase, the market demand for PP sheets, as a lightweight and recyclable plastic material, continues to grow. The technical level and performance of the sheet extruder directly affect the quality and output of the prepared PP sheet. Through continuous technological innovation and equipment improvement, the quality pp sheet extruder machine For sale has been continuously optimized to improve production efficiency, reduce energy consumption, and improve product performance to adapt to changing market needs.

Double Conical-Screw Extruding Sheeting Production Line:

Specifications of Double Conical-Screw Extruding Sheeter:

|

Item

Model |

Extrusion device |

Tabletting device |

Overall dimension |

Weight |

|||||||||||

|

Hopper

volume |

Screw

diameter |

Working length of screw |

Rotational speed of screw |

Motor

power |

Roller

diameter |

Roller

Length |

Nip adjustment |

Sheeting

width |

Linear

Speed of roller |

Motor power |

L |

W |

H |

||

|

L |

mm |

mm |

r/min |

KW |

mm |

mm |

mm |

mm |

m/min |

KW |

mm |

kg |

|||

|

XJPS- 75×350 |

150 |

Φ113/Φ335 |

710 |

5 ~18 |

22 ~30 |

Φ350 |

600 |

0.5~8 |

200~500 |

2.8~14 |

15~22 |

3330 |

2020 |

1680 |

8500 |

|

XJPS- 120×380 |

220 |

Φ165/Φ415 |

800 |

2~20 |

45 ~55 |

Φ380 |

700 |

0.5~10 |

200~600 |

2.8~16 |

30~45 |

3400 |

3150 |

1900 |

15000 |

|

XJPS- 160×400 |

300 |

Φ185/Φ455 |

850 |

2~20 |

75 ~90 |

Φ400 |

800 |

0.5~12 |

200~600 |

2.8~20 |

55~75 |

3650 |

4310 |

2100 |

22000

|

Previous:

Related products

Get product quotes for free

Our staff will contact you within 24 hours (working days). If you need other services, you are welcome to call the service hotline:0411-86666555

ADD

Room 3718,No.9-1.Haifu Road,Dalian Free Trade Zone,China(Liaoning)Free Trade Pilot Area

PRODUCTS